Abstract

Adoption of water-conservation irrigation practices could potentially reduce water and energy use and increase profitability, as well as protect the environment. Precision irrigation consisting of soil sensors (SS) for irrigation scheduling and variable rate irrigation (VRI) was compared with conventional uniform irrigation (URI). The study was conducted in South Alabama during the 2018 and 2019 corn growing seasons. The SS-VRI and URI treatments spanned the length of the field and were compared across five different management zones (MZ) that exhibited soil and terrain differences. Soil water tension sensors were installed on each MZ-treatment area to monitor hourly soil water changes. Results showed that on the two zones covering 55% of the study field, MZ 1 and MZ 2, the SS-VRI treatment, on a two-year average, resulted in 26% less irrigation water applied compared to the URI treatment; however, there were no statistical differences between yields or yield variability among treatments. Even though in MZ 4, there was not a substantial difference in irrigation water applied among treatments, soil sensors increased the precision of irrigation rate determination during the peak of high crop water demand. Findings from this study showed that as rainfall amount and distribution change over a crop growing period, soil sensor-based irrigation scheduling could be used to prevent over- or under irrigation. With proper management, the combination of soil sensors and VRI provides farmers with the opportunity to reduce water use, while increasing or maintaining yields; however, farmers must consider the investment and operating costs relative to the benefits.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Irrigation water is key to crop production due to its contribution to attainable yield, role on nutrient uptake (Sigua et al., 2017), and mitigation of heat and water stress to the crop (Lena et al., 2020; Mondaca-Duarte et al., 2020). Even with the importance of irrigation in agriculture, there are still many challenges associated with irrigation adoption, such as competition for freshwater with urban areas and industry, the increased irrigation demand for bioenergy crops, and lack of adoption of efficient irrigation systems and best irrigation management practices (USDA-ERS, 2019; WWAP, 2018). Agriculture water consumption accounts for 70% of the freshwater withdrawals in the world and, by 2025, this demand is expected to increase by 60% (Alexandratos & Bruinsma, 2012; Boretti & Rosa, 2019). Therefore, it is imperative to increase the use of technology, soil water sensors, and decision support tools for irrigation water management and to increase efficiency not only in water application but also in crop production (Andrade et al., 2016; Evett et al., 2020; Liakos et al., 2018; Rinaldi & He, 2014).

In recent years, farmers in the southeastern US have increased irrigation adoption as a risk management strategy to mitigate the impact of frequent droughts (Zipper et al., 2016), large summer rainfall variability (Stefanova et al., 2012), and to increase yield on soils with low water holding capacity and low fertility (Sigua et al., 2017). Alabama, for example, increased irrigated land from 46 000 to 66 100 ha between 2012 and 2018 (USDA-NASS, 2019); however, there is low adoption of technology or strategies for precision irrigation management. From 1 069 Alabama farms that reported the use of irrigation scheduling methods in 2018, 43% reported the use of the qualitative/empirical “feel the soil” method, 7.6% used soil water sensors, and 0.6% used daily crop evapotranspiration reports (USDA-NASS, 2019). The low adoption of irrigation scheduling methods may be linked to factors such as perceived benefits, cost, and farmers’ characteristics (e.g. socio-physiological variables and social norms), as well as their beliefs and attitudes (Cartwright et al., 2019). Overall, the use of efficient irrigation systems and best irrigation water management practices is crucial not only to maintain farm profitability (USDA-ERS, 2019) but also to prevent depletion of groundwater aquifers (Gleeson et al., 2012; Vories & Evett, 2014), protect aquatic endangered species, and/or ease water wars between geographic locations (https://blog.nationalgeographic.org/2016/08/19/how-smarter-irrigation-might-save-rare-mussels-and-ease-a-water-war/).

Irrigation scheduling, the process to determine irrigation rate and timing, may prevent crop water stress, as well as nutrient leaching and runoff that adversely impact crops and the environment (Taghvaeian et al., 2020). Two commonly used irrigation scheduling methods are crop evapotranspiration (Rogers, 2012; Sui & Voires, 2020) and soil water status (SWS) monitoring using soil water sensors (Irmak et al., 2010; Sui & Voires, 2020; Taghvaeian et al., 2020; Vellidis et al., 2008). Irrigation scheduling based on SWS requires actual real time soil sensor data, estimated values of field capacity (FC) and permanent wilting point (PWP), as well as the maximum amount of water the irrigation operator allows the crop to extract from the active root zone, or managed allowable depletion (MAD). Some irrigation specialists consider MAD as 50% but this value should be adjusted based on crop type, climate, soil type, and the irrigator’s knowledge (Rogers, 2012). Soil sensor data allows the irrigation operator to track SWS so it can be maintained above the irrigation threshold (MAD level) to prevent crop water stress and subsequently yield losses (Lena et al., 2020; Rogers, 2012). Several authors have reported multiple benefits from the use of this approach. The results of a 16 site-years study conducted in Nebraska by Irmak et al. (2012) showed that the use of soil water tension-based (SWT-based) irrigation scheduling resulted into 33% less irrigation water applied on corn with respect to the producer’s common irrigation practice, which represented energy savings ranging from 32.00 to 74.10 US$ ha−1. Vellidis et al. (2016b) found that SWT-based irrigation scheduling on cotton planted in South Georgia could reduce water application without impacting yield when compared to the traditional checkbook irrigation scheduling method. Leininger et al. (2019) evaluated different soil water tension sensor irrigation thresholds on a peanut study in Mississippi and documented crop yield, net return, and irrigation water use efficiency (IWUE) benefits. Although the crop evapotranspiration irrigation scheduling method has proven to be very effective, it requires keeping track of a water-balance on a daily basis, and for this reason many farmers and consultants do not use it much. The estimation of the soil water is done by keeping track of the incoming (irrigation and precipitation) and outgoing (crop evapotranspiration, runoff, and deep percolation) water in the root zone. When implemented correctly, the crop evapotranspiration irrigation scheduling method may also increase IWUE (Miller, Luck, et al., 2018; Miller, Vellidis, et al., 2018; Sui & Voires, 2020; Vellidis et al., 2016b). To facilitate proper and real-time implementation of this method, several smart irrigation phone applications (apps) are available for row crops (Vellidis et al., 2016b) and fruit and vegetables (Migliaccio et al., 2016; Miller et al., 2018a; 2018b).

Variable rate irrigation (VRI) is an irrigation water management strategy that allows irrigation systems to apply different irrigation rates as the system is in operation. When center pivot sprinkler irrigation systems are equipped with VRI systems, irrigation rates prescribed according to field variability can be applied using either speed or zone control methods (LaRue & Evans, 2012; Sui & Yan, 2017). In the speed control method, changes in the travel speed of the irrigation system are implemented to vary the water application. The downside of this method is that irrigation rates cannot be changed along the lateral pivot pipeline, which limits its applicability on fields with a high degree of spatial variability as changes in irrigation rates are only possible in the direction of travel. In contrast, the zone control method allows changes of irrigation rates along the lateral pivot pipeline as the pivot travels the field (Sui & Yan, 2017). Irrigation rate changes using the zone control method can occur by a single sprinkler or by a group of sprinklers. When this VRI application method is used, the pivot moves at a constant speed and uses a duty-cycle control method to control variation of sprinkler flow by changing the duty-cycle of individual sprinklers or groups of sprinklers along the pipeline (O’Shaughnessy et al., 2019; Sui & Yan, 2017). Variable rate irrigation systems use pneumatic or electric solenoid valves to control water application. The duty-cycle is the ratio of “on” time to the “on–off” time of a solenoid valve. The amount of water applied decreases as the duty-cycle decreases, and the sprinklers are completely turned off when the duty-cycle is zero (Zhao et al., 2015; Shi et al., 2019). Several studies have been conducted to how to best implement VRI and evaluate its benefits. Some of the major benefits reported are: an increase in crop yield and water use efficiency (Dahal et al., 2020; O’Shaughnessy et al., 2019; Sharma & Irmak, 2020; Spencer et al., 2019; Voires et al., 2020); reduction of leaching and soil erosion (Irmak et al., 2021; King et al., 2009; Pan et al., 2013; Sadler et al., 2005); and water-savings and better management of water deficits (Evans & King, 2012; Hedley & Yule, 2009; O’Shaughnessy et al., 2019; Spencer et al., 2019).

Even though there are numerous benefits resulting from VRI use, there are implementation challenges including determining the correct irrigation rate at the appropriate place within a field and the automation of these tasks. Plant water use and soil available water are influenced by biophysical and environmental factors and the proper implementation of the VRI method requires indirect and almost real-time assessment of both. For the implementation of VRI, some studies have evaluated the use of crop evapotranspiration (Irmak et al., 2021), soil texture and soil type (Sharma & Irmak, 2020; Sui & Yan, 2017; Voires et al. 2020), soil moisture (Vellidis et al., 2008; Zhao et al., 2018), and canopy temperature assessed by thermal infrared thermometers (Lena et al., 2020; O’Shaughnessy & Evett, 2010). Networks of soil water sensors (Vellidis et al., 2008) and canopy temperature sensors (O’Shaughnessy & Evett, 2010) equipped with wireless communication for data collection and transfer have been developed to monitor real-time soil water and plant response to both irrigation and rainfall and assist in the development and implementation of site-specific irrigation water management. These scientists have worked on the automation of the method in the form of decision support systems (Evett et al., 2020; O’Shaughnessy et al., 2015; Vellidis et al., 2016c).

Even with the documented benefits of using sensor-based irrigation scheduling and VRI, their adoption remains low across many areas of the US. Studies have indicated that low adoption occurs because farmers either lack information on costs and benefits or they do not have positive beliefs and attitudes towards their use of the technology (Cartwright et al., 2019; O’Shaughnessy et al., 2019). Researchers and irrigation industry recognize the complexity of implementing these practices and suggest fostering the creation of communities or peer-to-peer networks of producers to exchange knowledge and build skills (Rudnick et al., 2020), as well as training crop consultants and equipment dealers to help with implementation and troubleshooting (O’Shaughnessy et al., 2019). The group of scientists working on this study firmly believe that the adoption of precision irrigation strategies could increase if farmers are provided with information on implementation costs and benefits. The main objective of this on-farm demonstration study was to compare precision irrigation management (soil sensor-based irrigation scheduling and VRI) with conventional irrigation (uniform irrigation). The comparison between the management strategies was done in terms of the agronomic differences among the treatments. Additionally, economic considerations were discussed to start exploring the costs and benefits of precision irrigation management in southeast Alabama.

Materials and methods

Site description

The study was conducted on a 16.3 ha corn field under a center-pivot VRI system located in Samson, in southeast Alabama, US (31°07′03.0" N, 86°05′32.3" W) (Fig. 1). The study site was planted with corn continuously from 2017 to 2019; however, the experiment was carried out from March to August of the 2018 and 2019 corn growing seasons (Table 1). Dyna-Gro 57VP51 corn hybrid (Gyna-Gro Seed, Loveland Products, Products Inc., Loveland, CO, USA) was planted in both growing seasons and it has a relative maturity of 117 days. This corn hybrid was recommended for both dryland and irrigation conditions. Dates of planting, emergence, fertilization management, and harvest are provided in Table 1.

The predominant soil type of the study site is Eunola Sandy Loam (Fine-loamy, siliceous, semiactive, thermic Aquic Hapludults) (NRCS, 2011). The climate is characterized as humid subtropical (Cfa) based on Köppen–Geiger climate classification (Kottek et al., 2006) with a historical (2010–2020) summer (June–August) daily temperature of 26.7 °C and summer total and annual rainfall of 429 mm and 1 362 mm, respectively (https://mesonet.agron.iastate.edu/). A Spectrum WatchDog 2700 weather station was installed next to the study site to monitor hourly weather conditions (rainfall, temperature, soil radiation, wind speed and direction).

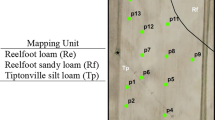

Management zone delineation and soil water monitoring for irrigation

The first step for the implementation of variable rate irrigation (VRI) is the delineation of homogeneous areas or zones within a field that exhibit differences between them (Fridgen et al., 2004). Several studies have found that soil moisture and yield variability correlate well with within-field variability of apparent soil electrical conductivity (soil ECa) and topography (Kitchen, et al., 2003; Martini et al., 2017), topographic wetness index (Maestrini & Basso, 2018; Reyes et al. 2019), and clay content and soil organic matter (Reyes et al., 2019; Xiangdong et al., 2019). In this study, management zones (MZ) were delineated based on soil ECa (Fig. 2a), terrain elevation (Fig. 2b), yield maps, and bare soil remote sensing images. A small tractor pulling a VERIS 3100® sensor (Veris Technologies Inc., Salina, KS, USA) was used for the collection of soil ECa data a week prior to spring planting. The soil moisture conditions at the time of data collection were neither too wet nor too dry because either scenario might prevent assessment of within-field variation of soil ECa. The soil moisture conditions can be described as optimum for planting and seed emergence. The tractor pulling the VERIS 3100® sensor was equipped with a Real-Time Kinematic (RTK) GPS (Trimble Inc., Sunnyvale, CA, USA) for collection of terrain elevation data. The VERIS 3100® sensor collected soil ECa at the depths of 0–0.3 m (shallow) and 0–0.9 m (deep). The Management Zone Analyst (MZA) software (Fridgen et al., 2004) was used for initial management zone delineation based on soil ECa (shallow and deep) and terrain elevation data (Bondesan et al., 2019). These initial zones guided identification of locations for soil texture sampling and determination of soil physical properties for irrigation purposes.

Five MZ were delineated prior to the 2018 growing season (Fig. 3a). In 2019, the MZ were revised and adjusted manually using the 2018 corn yield map and soil and crop remote sensing imagery, as well as knowledge of soil moisture variability gathered from the field in 2017 and 2018 (Fig. 3b). Although this study reports results from the irrigation treatment evaluation conducted in 2018 and 2019, a preliminary evaluation of those treatments conducted in 2017 increased knowledge of the within-field variability of yield and soil moisture variability and how to improve MZ delineations and best conduct the irrigation on-farm evaluation in the following years (Bondesan et al., 2019).

During the 2018 and 2019 growing seasons, the MZ were used to monitor soil water changes and to evaluate and implement VRI. The changes made to the 2018 MZ map, primarily in the southern portion of the field, consisted of an expansion of the eastern boundary of MZ 3 and contraction of the MZ 4 boundary. The differences between zones were verified using (1) soil texture data (Table 2) collected at the depths of 150 mm, 300 mm, and 600 mm from different locations within the field, (2) yield data, (3) soil water content monitored with sensors installed at different locations within the field (Bondesan et al., 2019), and (4) farmer knowledge of field variability.

To address the main objectives of the study, paired irrigation treatment strips traversing over each MZ were established to evaluate sensor-based irrigation scheduling and VRI (SS-VRI) water management strategies along with uniform irrigation (URI) (Fig. 4). These paired irrigation treatment strips were kept in the same sequence throughout the field (Fig 4a). One soil sensor probe was installed in each treatment-zone combination to monitor hourly changes in soil matric potential (SMP) and to determine irrigation amount for the SS-VRI treatment plots. For this study, soil sensor probes integrating three 200SS Watermark (Irrometer Company, Riverside, CA, USA) granular matrix sensors monitored SMP at 0.15, 0.30, and 0.6 m soil depths. The sensor probes were arranged in a wireless mesh network to allow communication and data transfer between sensors and a base station installed in the field and delivered to a remotely located server (Sui & Baggard, 2015; Vellidis et al., 2008, 2016a). A web-interface developed by Vellidis et al. (2013) allowed remote access and visualization of hourly data. Each sensor probe was installed in the center of each treatment-zone field plot area, located in the crop row between two healthy corn plants. For installation of each soil probe, a hole was dug using an auger with a similar diameter to the sensor probe. A slurry was prepared with soil collected from each hole and was poured to the midway point of the hole. The sensor probe was inserted into the hole and the remainder of the slurry was used to back-fill the hole, after removing any air pockets.

Although SMP sensors correlate with plant water stress as they provide measurements analogous to the force needed by plants to extract water from the soil (Irmak et al., 2006; Kramer, 1963), the SMP values were converted to soil water content using data from site-specific soil water retention curves (SWRC) determined from locations within each MZ. Eight locations were selected for collection of undisturbed soil samples at soil depths of 0.15, 0.30, and 0.60 m. Two locations were selected in MZ 1, MZ 2, and MZ 4 and one location in MZ 3 and MZ 5 (zones with less field area coverage). Every location-soil depth sample was used for determining a SWRC and the associated field capacity (FC) and permanent wilting point (PWP) values. The soil texture and soil bulk density data and plant-available water (PAW) were also estimated for each location-soil depth. Table 2 shows average values of the main soil physical characteristics of each MZ at the 0.30 m soil depth.

Several SWRC and respective values of FC and PWP were generated from data collected from soil samples processed using the hydraulic property analyzer (HYPROP 2, Meter Group, Pullman, WA, USA) and a dew point hygrometer (WP4C Potential Meter, Meter Group, Pullman, WA, USA) sensors. Undisturbed soil samples were placed on the HYPROP 2 sensor (Meter Group, Pullman, WA, USA) to determine the relationship between volumetric soil water content (VWC) and soil matric potential between the rage of 0–0.08 MPa (Shokrana and Ghane 2020). For the dry end of the SWRC curve, the WP4C sensor (Meter Group, Pullman, WA, USA) was used to determine the VWC at soil matric potential of 0.63, 1.5, and 3.3 MPa. All data collected were input into the HYPROP-FIT software ver. 4.1.0.0 (Meter Group, Pullman, WA, USA) to determine the SWRC parameters. The traditional unconstrained van Genuchten model was used to fit the SWRC and estimate the model parameters (van Genuchten, 1980). For the sandy and loamy sand soil samples (light soils), the VWC at FC was selected at the pressure of 10 kPa and for the other soil samples with sandy clay loam and sandy loam texture, the soil tension at 33 kPa was selected for estimation of VWC at FC (Table 2) (Alves de Oliveira et al., 2015). Soil bulk density was calculated as the weight of dry soil (oven-dried at 105 °C until constant weight) per unit of volume using undisturbed soil cores.

Comparison between irrigation practices and irrigation scheduling

Comparison of the SS-VRI and URI practices was conducted under a 393 m Zimmatic (Lindsay Mfg. Co., Omaha, NE, USA) Center Pivot with a Lindsay® Growsmart precision VRI system. The pivot had seven spans and 36 solenoid valves controlled the irrigation rate of 142 nozzles. It operated at a water flow of 181 m3 h−1 and the mid-elevation spray application (MESA) application package was equipped with 103 kPa pressure regulators and spinner spray heads. Paired irrigation treatment strips (SS-VRI and URI), averaging 80 m wide, were used to evaluate both irrigation strategies in this study (Fig. 4). There were nine URI treatment plots in 2018 and eight URI treatment plots in 2019. There were eight SS-VRI treatment plots during both growing seasons.

The SS-VRI treatment consisted of the application of MZ-specific irrigation rates estimated using real time data from SMP sensor probes installed in each treatment-zone area. The SMP data were converted into VWC using the in situ (MZ and depth specific) derived SWRC. The values of FC and PWP generated from each SWRC at each soil depth were used to calculate available water holding capacity. Irrigation application was triggered when the VWC reached 25% depletion from available soil water holding capacity in the top 0.6 m of soil. The irrigation rate was estimated as the amount necessary to bring the soil back to field capacity water content either using one or two consecutive rotations of the center pivot irrigation system. During the corn growth stages prior to flowering, data from soil sensors at the depths of 0.15 m and 0.30 m was combined into a soil depth weighted average to determine the irrigation rate. After flowering, the VWC weighted average value included VWC data from all three soil sensor depths. Because MZ 1, MZ 2, and MZ 4 were the largest zones on the study field, the data from two soil sensors probes installed on two treatment-zone areas was averaged to estimate the final irrigation rate used in the VRI map. In 2018, VRI only started at the blister (R2) growth stage and, prior to that, the SS-VRI treatment plots received the same rate as the URI treatment plots. In 2019, VRI started at the V7 growth stage. In both years, the final irrigation rate was corrected by the pivot irrigation efficiency (90%), and 2.5 mm of water per irrigation event was added to the estimated rate based on soil sensor data. In 2019, the amount of one day crop water uptake, the difference between real-time soil water status (VWC) and VWC at FC, estimated the day prior to each irrigation event was added to the final irrigation rate to account for the additional crop water use that occurred during the time the irrigation system traversed the field on a single pivot revolution. Once the irrigation prescription for the SS-VRI treatments was calculated and the farmer decided on the URI treatment irrigation rate, a prescription map was prepared in the FieldMap™ software (Lindsay Mfg. Co., Omaha, NE, USA) and uploaded to the variable rate panel either by a thumb drive or remotely.

Although the cooperating farmer used several sources of data to decide on irrigation rates and timing for the URI treatment, for the purpose of this study, the farmer’s irrigation scheduling approach is described as the evapotranspiration-based irrigation scheduling method. Prior to the initiation of this study, the farmer was attempting to use the VRI system, and had studied soil physical properties, such as saturated hydraulic conductivity and available water storage in the soil profile provided in the NRCS soil survey (NRCS, 2011). Rain and irrigation water were water inputs for the water balance and the output was weekly crop water use (crop evapotranspiration). The farmer recorded changes of weekly crop growth and crop water use was gathered from extension bulletins (University of Georgia, 2021). In 2018, the farmer combined this information to schedule irrigation on the URI treatment areas. In 2019, the treatments remained the same; however, irrigation scheduling on the URI treatments was based on the recommendations of the FieldNET Advisor™ (FNA) (Lindsay Corporation, Omaha, NE) cloud-based irrigation management tool. FieldNET Advisor™ is a crop growth model-based irrigation scheduling tool that uses the soil water balance model and incorporates real-time weather data to prescribe irrigation rate and timing. At the start of the 2019 growing season, FNA was expected to prescribe different irrigation rates to the five MZ; however, the irrigation rate recommended by FNA was the same for each MZ with changes only in irrigation timing between MZ. Because the center pivot irrigation system covers the study field and other fields planted with a crop with different water requirements, the farmer was the primary decision maker on when to start irrigation; however, the farmer welcomed advice from the study team. In 2019, if irrigation was required in the study area, the URI and SS-VRI prescriptions were adjusted in order to allow the pivot to make at least one revolution per day and then allow for irrigation of the other areas under the pivot on a short revisiting time. One pivot revolution per day was achieved when the irrigation prescriptions did not exceed approximately 15 mm of irrigation depth. During periods of high crop water demand and no rain, the total prescribed irrigation rate was split in half to allow the pivot to complete an entire revolution per day. To complete the recommended total irrigation prescriptions, the pivot passed by the study area on two consecutive days.

Yield response to irrigation

Yield monitor data was used to evaluate yield differences between irrigation treatments and treatments by MZ. The corn was harvested with a six-row John Deere 9570 STS (Bullet Rotor) grain combine equipped with a yield monitor. At the time of harvest, the yield monitor was calibrated for grain weight and moisture with corn grain coming from the experimental field. A combine head-width strip running throughout the length of the field and covering most of the field variability was harvested for yield monitor calibration. In 2019, additional evaluation of yield monitor accuracy was conducted by hand-harvesting corn grain samples (six rows of 1 m length) from areas adjacent to the soil sensor locations within each MZ. This evaluation was conducted to verify the accuracy of the grain combine yield monitor (Fig. 5). Prior to data analysis, the grain yield was normalized to 15.5% moisture content and reported on a weight per unit area basis.

Yield data visualization, cleaning, and analysis was done with the QGIS software platform (QGIS. Development Team, Open Source Geospatial Foundation Project). Very low yield data points that generally appeared around the field edges were removed manually from the data set. To account for overspray of adjacent pivot nozzles and the irrigation rate transition between each MZ-treatment area, a 10-m buffer zone was created on all sides of each treatment area and yield data points within the buffer areas were not included in the analyses. The buffer width criteria were based on the ability of the center pivot irrigation system to change from one irrigation rate to another while traversing the field. The Lindsay® Growsmart precision VRI system gradually changes the irrigation rate when traversing from one MZ to another and this change, measured in the field, occurred over a 10 m distance.

The yield by treatment-MZ was estimated as the average value of the data points within each treatment area after the removal of yield data points within each buffer area. The number of data points within each treatment area was included as a weight factor into the estimation. The standard deviation of each treatment-zone area was also estimated to evaluate the degree of variability between the treatments and the impact of irrigation practices on yield variability. Crop Water Use Efficiency (CWUE) was estimated and used in the evaluation of the different irrigation strategies. The CWUE was calculated by dividing the yield per treatment-MZ by the seasonal crop evapotranspiration (ETa, mm) per treatment-MZ measured over the growing season (Irmak, 2015) (Eq. 1).

Seasonal ETa was derived and estimated from the soil water balance equation (Evett et al., 2002):

where P = precipitation from planting to physiological maturity; I = total irrigation applied per treatment (mm); F is the flux across the lower boundary of the control volume (taken as positive when entering the control volume); ΔSWS = change in soil water stored in the soil profile as determined by soil sensors (soil sensor data at physiological maturity minus initial soil water measurement). For the specific purposes of this study the values of runoff and F were assumed negligible (O’Shaughnessy et al., 2012).

Statistical analysis

The evaluation of the differences between MZ, year, and treatments, as well as their interactions, were tested using yield, yield standard deviation, and CWUE. Response data were analyzed using linear mixed model methodology as implemented in SAS® PROC GLIMMIX (SAS/STAT 15.2; SAS Institute, Cary, NC) based on a model where soil sensor was nested within treatment, i.e., a completely randomized design (CRD). Because the soil sensors and irrigation treatments remained in place for the second season, this experiment is of a repeated nature. R-side modeling tested two possible covariance models, compound symmetric (CS) and compound symmetric with heterogeneous variances (CSH), where the latter allows each year to have its own variance. The number of yield points for each treatment-zone combination was used as a weighting factor because the number of observations differed as much as sevenfold. Based on the penalized Akaike Information criterion (AICC) fit statistic, the CS model was chosen as the appropriate covariance model. Management zones, irrigation treatments, year, and all their interactions were treated as fixed effects. Three-way interaction least squares means were calculated, and irrigation treatments were compared within each MZ by year combination using the SLICEDIFF option of LSMEANS within the procedure outlined above.

Results and discussion

Weather conditions and irrigation management

On average, both study years were warmer than the last nine-year average (2011–2020) (Table 3). The cumulative rainfall during the 2018 growing season, 792 mm, was greater than the 2019 season, 541 mm (Fig. 6). From planting to the R1 growth stage, both seasons registered a cumulative rainfall below the last nine years’ historic (2011–2020) cumulative average values. However, in 2018, the cumulative rainfall during the reproductive corn growth stages (R1–R6 stages) until harvest was greater than the historic records and the 2019 season. The 2019 cumulative growing season rainfall was below historic values and the 2018 season, especially during the reproductive growth stages (R1–R6 growth stages), which explains the total irrigation differences between the study years (Figs. 6, 7). While planting was seven days earlier in 2018 than in 2019 due to more favorable weather conditions at planting, the corn tasseled earlier in 2019 than in 2018 which could be associated with the hotter and drier conditions registered in 2019 (Table 3). Overall, in both years, the physiological maturity occurred around the same season length (108/109 days after planting).

Total irrigation on both irrigation treatments was greater in 2019 than in the 2018 growing season (Figs. 7, 8). Irrigation differences might be explained by the higher monthly ambient temperature and vapor pressure deficit and lower rainfall registered in 2019 which could have influenced evaporative demand and transpiration (Howell et al., 1995; Sharma & Irmak, 2021) (Table 3). The lower relative humidity registered in 2019 could be associated with the lower rainfall registered that year (Table 3). There were differences in total irrigation between the two irrigation strategies by MZ in 2018 and 2019 (Fig. 7). On average and across MZ, the SS-VRI treatment applied 34% and 11% less water than the URI treatment in 2018 and 2019, respectively. Similar results were found by Sui and Yan (2017) evaluating the same practices, SS-VRI and URI, on corn and soybean growing in an experimental field in Mississippi. Their water use efficiency results indicated that SS-VRI was superior to URI, with SS-VRI using 25% less irrigation water than URI. In both years of this study, the SS-VRI treatment implemented on MZ 1, MZ 2, and MZ 5 resulted in lower irrigation amounts compared to URI (Figs. 7, 8). These three MZs covered 75% of the total studied field and, therefore, these results indicate that the risk of a possible over application of water across those zones would be minimized with the use of soil water sensors and VRI. Zhao et al. (2018), comparing VRI and URI irrigation strategies in a semi-humid environment, reported that when there was ample rainfall, the use of VRI resulted in a lower amount of water applied compared to the URI treatment. These results agree with the findings of this study (Fig. 7, Table 3). The use of VRI and soil sensors improved irrigation water management by reducing the number of applications and amount of water applied, and by allowing site-specific application of irrigation water especially during the wet 2018 season (Figs. 6, 7). Once the VRI started in both growing seasons, nine irrigation events occurred in 2018 compared to 15 irrigation events in 2019 (Fig. 8). In 2018, the SS-VRI treatment was implemented only after the silking growth stage (R1 stage) because of delays in VRI maintenance and data availability. Prior to silking, 54.4 mm of irrigation water was uniformly applied across the study field. Even though the cumulative rainfall during the 2018 corn reproductive stages (R1–R6 stages) was above the last nine years, the SS-VRI treatment scheduled and applied different irrigation rates to various zones to either prevent water deficit during the periods where the rainfall did not meet crop water needs or to reduce the irrigation rates on areas when there was a reduction in or elimination of the need for irrigation (Figs. 7, 8). The wetter growing season observed in 2018 exemplifies the importance of using soil water sensor data to avoid unnecessary irrigation applications or over-irrigation, as well as better allocation of water. The drier 2019 growing season, on the other hand, exemplifies the importance of creating VRI prescriptions to better adapt the irrigation rates to account for crop water needs and soil water availability especially during the reproductive growth stage in which water deficit could potentially increase the risk for yield loss.

Effect of zone on corn yield

There were statistically significant yield differences between MZs (average of all treatments within each zone), years, and year by zone (P < 0.05; Table 4). The average grain yield in 2019 was higher than 2018; however, in most cases the relative differences between low and high yielding zones remained stable across the studied years (Fig. 9a, b). In 2019, average corn yield on MZ 1, MZ 2, and MZ 3 exceeded average corn yields in 2018. Crop water use efficiency changed among years, zones, and treatments and especially greater in 2019 where some zones received less irrigation even though rainfall was lower than in 2018 (Table 4, Fig. 9d). In both years, MZ 2 (sandy loam soil in the top 220 mm) was the highest yielding and second highest yielding zone compared to the other MZs in 2018 and 2019, respectively. This zone also exhibited the highest CWUE compared to the other MZs (Fig. 9c, d). The second highest yielding zone in 2018 was MZ 1 (sandy clay loam soil in the top 220 mm) and, in 2019, MZ 1 was the third highest yielding. In contrast, MZ 4 (sandy soil in the top 220 mm) was the lowest yielding and CWUE zone in both years. These results are likely related to soil texture, PAW, and terrain elevation differences between zones (Table 2, Fig. 2a, b) (Mamedov et al., 2001; Vories et al., 2020; Wakindiki & Ben-Hur, 2002). The PAWof MZ 1 and MZ 2 estimated at 300 mm soil depth was approximately 53 mm and 65 mm, respectively, while MZ 4 had a PAW of 30 mm (Table 2). Thus, MZ 1 and MZ 2 had a greater ability to store water than MZ 4, which likely impacted irrigation frequency and rate. The fact that MZ 4 had between 43 and 54% less PAW and lower soil water holding capacity than MZ 1 and MZ 2 explains why it was necessary to apply more irrigation water across MZ 4 in both years (Fig. 7).

Mean of yield (Mg ha−1) (a, b) and crop water use efficiency (CWUE) (Kg m−3) (c, d) in the soil sensor based variable rate irrigation (SS-VRI) and uniform rate irrigation (URI) treatments for each management zone during the 2018 and 2019 growing seasons. Note: Significant yield differences among treatments within each zone are indicated with P-values

The average yield across treatments on MZ 3 (Loamy sand in the top 22 cm) compared to the other MZ varied across years (MZ x Year interaction, Table 4). In 2018, MZ 3 had the third highest yield after MZ 2 (highest) and MZ 1 (second). In 2019, MZ 3 out yielded the other four MZ with an almost 10% yield increase above the average corn yield for the field and approximately 50% increase when compared to MZ 4, the lowest yielding zone in 2019. These results were expected because crop yield is the result of the crop interaction with soil, weather conditions, and management (Sharma & Irmak, 2021) (Tables 2, 3). Overall, in 2019, more frequent and a greater number of irrigation events were scheduled compared to 2018; therefore, it is possible that the risk of crop water stress was minimized in 2019. In MZ 3 in 2019, the SS-VRI treatment had the second highest yield compared to the other zones. Management Zone 3 includes the low-lying topographic position of that part of the study area, no considering MZ 4, and the water drainage lines (Fig. 3b) suggest that there is a likelihood of water and nutrient runoff moving from MZ 2 towards MZ 3. Some of the factors that might explain the yield increase on MZ 3 in 2019 are greater among of irrigation water applied compared MZ 1 and 2; possible surface water runoff from other zones into MZ 3, and better soil water drainage (Sharma & Irmak, 2021; Sui & Yan, 2017).

Management Zone 5 had the fourth highest crop yield across MZ in both years. The soils and PAW in this zone are comparable with MZ 4; however, data from soil sensors installed in MZ 5 indicated soil moisture levels greater than MZ 4 during both growing seasons.

The yield differences among the zones and the influence of weather conditions (year interaction) demonstrate how different processes influence yield variability and irrigation requirements. Previous studies have reported that high yielding zones had low soil ECa values (Sharma & Irmak, 2021; Sui & Yan, 2017). In Sharma and Irmak (2021) study, the high yielding zone was characterized as a silt loam soil with 0–1% slope and an average soil ECa shallow of 48.67 mS/m. In the Sui and Yan (2017) study, the high yielding zone exhibited a soil ECa deep (0–0.9 m) range of 4.3–41.5 mS/m. In this study, the field’s soil ECa shallow (0–0.3 m) ranged from 0.5 to 18.7 mS/m (Fig. 2a) which are low values compared to the Sharma and Irmak (2021) and Sui and Yan (2017) studies. The highest yielding zone, MZ 2, exhibited soil ECa values slightly lower than MZ 1 but greater than MZ 4 and MZ 3; however, a high degree of soil ECa variability was observed (2.6–10.5 mS/m). In contrast, the two lowest yielding zones, MZ 4 and MZ 5, had the lowest soil ECa values (< 2.6 mS/m) (Fig. 2a).

Another factor possibly influencing crop yield and the crop response to irrigation was terrain elevation. Terrain elevation was lower on MZ 2 compared to MZ 1 and MZ 4 which may also explain yield differences (Fig. 2b). Kravchenko and Bullock (2000) found a negative correlation between topography and corn yield which agrees with the yield differences in MZ 2 and MZ 3 (specifically in 2019) compared to MZ 1. Low lying terrain areas have been associated with soil water accumulation, saturation overland flow, and small soil sediment deposition overtime which positively influences yield in dry years and negatively impacts yields in wet years (Maestrini & Basso, 2018; Reyes et al., 2019).

Crop response to irrigation treatments within management zones

Timely irrigation water during the 2019 growing season mitigated the lack of rainfall and high ambient temperatures and may explain higher corn yields observed primarily on MZ 1, MZ 2, and MZ 3 compared to the 2018 growing season. Sharma and Irmak (2021) associated corn yield increase to high temperatures, evaporative demand, and sufficient water in the soil profile. The greater soil water availability on MZ 1 and MZ 2 along with better irrigation management, both timing and rate, as well as the favorable weather conditions for plant transpiration (Table 3), potentially influenced the 13% and 19% average yield gain in 2019 compared to the 2018 season on MZ 1 and MZ 2, respectively (Fig. 9a) (Howell et al., 1995; Sharma & Irmak, 2021).

Although differences existed between irrigation treatments (SS-VRI and URI) in both studied years (Fig. 7), there were no statistically significant yield differences among irrigation treatments by MZ (P = 0.142) when data from both studied years were combined (Table 4). In contrast, the interaction MZ × Irrigation treatment was significant (P = 0.002). Fifty-five percent of the studied area was covered by MZ 1 and MZ 2 and there were no statistically significant yield differences from the application of less irrigation water by the SS-VRI treatment compared to the URI treatment but the CWUE of the SS-VRI was greater in both years (Figs. 7 and 9a). These two zones had the highest plant available water (Table 2) and, therefore, the results demonstrate that similar yields are achievable with less irrigation water as in SS-VRI treatment (Fig. 7). In MZ 1, the SS-VRI treatment resulted in 35% and 29% less water applied compared to the URI treatment in 2018 and 2019, respectively. Traditionally, farmers operating near the study field apply between 19.5 and 25.4 mm per irrigation event. Assuming that the average farmer’s practice is to apply 25.4 mm per irrigation event, the use of the SS-VRI treatment in MZ 1 would have resulted in 1.7 and 2.7 less irrigation events across the 1.2 hectare zone in 2018 and 2019, respectively (Fig. 8). Although there were not statistically significant yield differences among irrigation treatments within MZ1, there were CWUE differences. The CWUE of the SS-VRI treatment was 3.9% and 17% greater than URI in 2018 and 2019, respectively (Figs. 9, 10). The greater CWUE differences between the SS-VRI and URI treatments in 2019 are related to total irrigation applied (Figs. 7, 8). This zone exhibits the highest terrain elevation values than the other zones and the second highest PAW value after MZ 2. Sharma and Irmak (2021) compared variable rate fertigation and VRI, and found the greatest yield on the higher elevation soils and lower yields on low-lying areas prone to water ponding on wet years. Although MZ 1 is among the high-yielding zones, the likelihood of topography-driven soil water movement and water loss (Kitchen et al., 2003; Kravchenko & Bullock, 2000; Maestrini & Basso, 2018) could have been mitigated by a greater soil water holding capacity. These data show that the combination soil sensors to schedule irrigation and VRI to deliver water according to the crop needs is key to addressing within-field soil and topography differences that influence soil water and crop growth and that these two water management strategies contributed to less water application on this zone. Liakos et al. (2018), evaluating SS-VRI and URI treatments during one cotton growing season under a humid subtropical climate, found that the VRI irrigation management approach resulted in greater yields and less irrigation water application.

Mean of yield standard deviation (Yield Std) (Mg ha−1) in the soil sensor based-variable rate irrigation (SS-VRI) and uniform rate irrigation (URI) irrigation treatments for each management zone during the 2018 (a) and 2019 (b) growing seasons. Note: Significant differences among treatments within each zone are indicated with P-values

Across MZ 2, the largest zone covering 37% of the study area, the SS-VRI treatment resulted in 43% and 22% less water applied compared to the URI treatment in 2018 and 2019, respectively (Fig. 7). No statistically significant yield differences or yield variability were observed as a result of the lower irrigation rates applied by the SS-VRI treatment (Figs. 9a, 10). The CWUE difference in the SS-VRI treatment was 6.1% and 13% greater than URI in 2018 and 2019, respectively (Figs. 9, 10). In 2018, the use of the SS-VRI treatment resulted in the greatest CWUE increase compared to the other zones and in 2019, it resulted in the second largest CWUE increase. Compared to MZ 1 and MZ 4, MZ 2 had lower terrain elevation and is characterized as a drainage basin due to several natural water surface drainage channels running through the zone in the east to west and west to east direction. The likelihood of water runoff and water accumulation in this zone may have contributed to the lower amounts of irrigation water applied under the SS-VRI treatment compared to the URI treatment. Because MZ 2 is characterized as a sandy loam soil, the potential impact of water ponding is lower compared to MZ 1, which is a sandy clay loam soil.

In both years, the zone where SS-VRI resulted in the lowest yields compared to the URI treatment was MZ 3. Unlike in 2019, there was a significantly different yield between treatments (P = 0.058) in 2018 (Fig. 9a). Among treatments, the SS-VRI treatment also exhibited the greatest significantly different yield variability (Fig. 10). In both years of the study, the CWUE of SS-VRI was lower than the URI treatment and this could be explained by the lower yield measured on that treatment (Fig. 9c, d). As explained above, several factors, in addition to the low irrigation amounts applied in 2018, could have contributed to the lower 2018 yield and higher yield variability. The yield and total irrigation applied on this zone in 2018 indicated that perhaps the FC threshold tension value used in 2018 was too high for that type of soil, resulting in less irrigation being recommended. The FC threshold for this zone was modified for the second year of the study. In 2019, there were no differences between treatments; therefore, the lower yield in 2018 and greater yield variability observed in the SS-VRI treatment (Figs. 9a, 10a) could be related to the intrinsic variability of the area and the low irrigation applied. (Fig. 2).

Management zone 4 was the only area where the SS-VRI treatment resulted in higher irrigation water amounts compared to the URI treatment (Fig. 7). This zone exhibited higher terrain elevation compared with MZ 2, MZ 3, and MZ 5 and it had the second lowest PAW. These two factors may have influenced the rate of soil water depletion resulting in a higher irrigation water demand than the other zones. In both study years, the SS-VRI treatment resulted in higher yields compared to the URI treatment but statistically significant differences among treatments were found only in 2019 (Fig. 9b). Although the cumulative irrigation differences between both treatments were small (25.7 mm), most of the irrigation application rate differences between the treatments occurred during the blister (R2) and milk (R3) growth stages, when the crop water demand was very high (Fig. 8b) and may have subsequently influenced yields (Fig. 9a). The use of soil sensors in this zone contributed to better determining when and how much to irrigate in comparison to other zones, thereby minimizing the risk for yield loss associated with water stress (Vories et al., 2020). Although the irrigation application rate differences among the treatments was not as large as observed in other zones, the CWUE in the SS-VRI treatment was significantly greater than the URI treatment. The CWUE in the SS-VRI treatment was 9.7% and 11.3% greater than URI treatment in 2018 and 2019, respectively.

During the 2018 growing season on MZ 5, the SS-VRI treatment resulted in 26% less irrigation compared to the URI treatment (Fig. 7); however, no statistically significant yield differences were observed among the treatments (Fig. 9a) (P = 0.526). Although MZ 5 had soil properties comparable to MZ 4, the average lowest yielding zone, the soil sensors installed on MZ 5 indicated in both years that soil moisture was higher when compared to MZ 4. The proximity of MZ 5 to a creek (150 m) and the light soil texture could have favored a high water table that would not have been detected without the use of the soil sensors. In the 2018 season specifically, during the wet blister growing period (R2 growth stage) the use of soil sensors and VRI resulted in lower irrigation rate and in the end contributed to an average 33% water savings (Fig. 7a) which was reflected in the CWUE increase and the significant CWUE differences between irrigation treatments (Fig. 9c). Significant yield variability differences among irrigation treatments were observed in both years (Figs. 10, 11). This may have influenced the yield differences between treatments and masked the yield response to irrigation, especially in 2018.

Across years, the SS-VRI treatment exhibited significantly greater CWUE than the URI treatment in four out of the five zones with greater differences on MZ 1 and 2 that cover 55% of the cropped area which shows that the use of soil sensors and VRI are water management strategies that can contribute to water savings without impacting crop yield.

Economic considerations of variable rate irrigation and soil sensors

When adopting new technology, particularly variable rate technology, growers must consider the potential for a positive return on investment, or the financial feasibility of an investment While it is common to focus on variable production costs, investment and ownership costs (commonly referred to as fixed production costs) are important to consider for success in the long-run. Investments in VRI and soil sensors should be part of that equation. However, it is not just about investing in the technology but effectively and efficiently utilizing the technology. If a grower invests in a center pivot fitted for VRI but does not utilize the VRI system, it limits the potential for a positive return on investment. The adoption of soil sensors increases a grower’s ability to maximize IWUE if the sensor data and VRI are properly managed by the grower.

There are several considerations related to the adoption of soil sensors that must be considered by interested farmers. The soil sensors utilized in this study cost approximately 450 US$ sensor−1 and the lifespan is assumed to be 4 years. Assuming an interest rate of 4.5% (Runge et al., 2021), the annualized cost (over 3-years) is 125.43 US$ sensor−1. Additionally, each sensor is required to have a data plan for remote access of data via phone or web, which increases the annual cost by 113 US$ sensor−1. The cost of the sensor and required data plan is dependent on the type of sensor, the typical life, and the availability and cost of data plans. In this study, the total annualized cost of the sensor was assumed to be 238.43 US$ sensor−1.

The per hectare cost of the sensor is dependent on the number of hectares within the management zone covered by the sensor, as well as the annualized cost of the sensor. In this study, there were at least two sensors per zone and the MZ ranged in size from 1.8 hectares to 6 hectares, with the VRI treatment only on a portion of each zone. The placement of individual sensors within treatment areas was necessary for research purposes; however, a grower may use a single sensor per management zone and have larger MZ based on the field. For a MZ covered by a single sensor, the additional cost of the sensor and data plan would have to be covered by an increase in yield, a decrease in water use, or a combination of both within the MZ equivalent to the investment cost to be financially feasible and have a positive return on investment. For yield, assuming a corn price of 167 US$ Mg−1, the overall yield in the MZ would need to increase by approximately 1.42 Mg of corn. On average, if the MZ was 6 hectares the average yield would need to increase by 0.54 Mg ha−1. However, it is important to note there are other variable production costs, such as drying and hauling, that are yield dependent and will also increase with a yield increase. Additionally, the necessary yield increase is dependent on the price of corn, as the price of corn received by the grower increases, a positive return on investment can be realized at smaller increases in yields.

Estimating energy use for an irrigation water pumping system and center pivot is complicated by the boundaries of the different irrigation zones or the different fields covered by a single VRI system, the size of the pump, the cost of electricity or diesel fuel, and the management experience of the operator. Additionally, some farmers use irrigation reservoirs to store water during the wet winter months for use during the growing season. In some cases, water is pumped from a river into the reservoir and then is pumped from the reservoir to the pivot system, and the additional pumping costs should be factored into the cost of irrigating. Typically, throughout the southeastern US, farmers do not pay for water on a per unit basis, as it common in the western US. The cost of irrigation is usually the irrigation investment cost, energy costs to pump the water and run the pivot, management time, and repairs and maintenance. Assuming the variable operating cost of the irrigation system is 0.47 US$ mm−1 (Runge et al., 2021) and yields remain unchanged, overall water use in the MZ would have to decrease by 505 mm to cover the soil sensor investment costs through reduced energy costs, which is assumed to be a proxy for the price of water. It is unlikely that either scenario (yield increases and decreased water use) will exist without other changes in either variable operating costs or yield.

The benefits of soil sensors go beyond the financial feasibility on a single field, extending to the economic feasibility of the farming operation. Due to the lack of aquifers in Alabama, many irrigators pump water from surface water sources, such as rivers or irrigation retention ponds. Depending on the number of pivots pulling water from a reservoir, there may be limited water resources to adequately irrigate all fields. Using soil sensors and VRI may increase IWUE and allow water to be used more efficiently across multiple fields by adequately addressing the water needs of the crop based on the data from the soil sensors. This potentially allows for increased yields (lower yield variability) across multiple fields due to more acres produced without water stress. Additionally, increasing water use efficiency has benefits to society, which are more difficult to quantify, such as improved flow of adjacent water courses and reduced soil surface runoff due to improved infiltration (Sadler et al., 2005).

For a clear understanding of the profitability of irrigation, including VRI and soil sensors, it is helpful to keep detailed records of when irrigation occurs, how much water is applied, the amount of management required for an irrigation event and across the growing season, the actual time for the pivot to make a complete cycle, energy use, and repairs and maintenance. Each farm and irrigation system are different due to limitations that are site specific. Without adequate record-keeping, it is difficult to identify the economic costs and benefits of SS-VRI.

Conclusions

The impacts of precision irrigation (SS-VRI) and URI were evaluated in a 2-year study in southeastern Alabama, US. The comparison of these two irrigation water management strategies was conducted on a field with spatial soil and terrain differences. The main findings and conclusions of this study are summarized as:

-

Irrigation differences among years and zone-treatments were influenced not only by the different monthly rainfall amounts but also other weather conditions like temperature and vapor pressure deficit as well as the soil and within-field topographic variability.

-

The value of irrigation and precision irrigation was better demonstrated and evaluated during 2019, the year with monthly rainfall below and ambient temperature above historic values. The possibly higher evaporative demand experienced by the crop in 2019 was mitigated using soil sensors and VRI to precisely apply irrigation amounts according to the crop needs within each MZ.

-

The yield differences between MZ in both studied years could have been associated with soil texture and terrain elevation variability which might have influenced soil water availability, soil water accumulation, and overland flow. In two high yielding zones (MZ 1 and MZ 2), covering 55% of the study area, the greatest water savings resulted from the use of soil sensors and VRI (SS-VRI treatment). The 2-year irrigation average showed 32% water savings from the SS-VRI treatment compared to the URI treatment on those zones without a negative impact on yields.

-

Terrain elevation, soil texture, overland flow, and possibly subsurface lateral water movement influenced soil moisture and plant available water. Each one of the five MZ were influenced differently by these factors and the weather. Therefore, the results from this study demonstrate how soil sensors assessed the within-field daily soil moisture differences and the subsequent response of the crop to these factors. For example, both MZ 4 and MZ 5 have similar soil texture conditions; however, these zones have different terrain elevation characteristics and MZ 5 is near a creek. In 2018, the SS-VRI treatment on MZ 5 resulted in 32% less irrigation compared to the URI treatment, while the same treatment prescribed more irrigation on MZ 4. Without soil sensors, or another method to assess within-field daily soil water and crop water use, the farmer could have over- or under-irrigated various zones in the field.

-

Greater CWUE and water savings from the use of soil sensors and VRI combined were observed on the zones with high soil water holding capacity, MZ 1 and MZ 2, contrasting with MZ 4 with the lowest soil water holding capacity where no water savings were observed between irrigation treatments. However, these differences show the benefits of using technology to precisely apply irrigation water according to crop and within field variability.

-

The greatest CWUE increase using the SS-VRI treatment was observed in 2019, the season with lower rainfall amount and greater evapotranspiration. These results suggest the importance of soil sensors and VRI to better determine timing and amount of irrigation as well as better irrigation water placement.

-

The role of soil texture and terrain elevation on soil water changes and ultimately irrigation prescriptions implemented in the SS-VRI treatment suggests that terrain elevation and other topographic-related variables should be used for irrigation management zone delineation. Results from other research studies found that the topographic wetness index (TWI), derived from terrain elevation, could explain a large position of spatial and temporal yield variability. Therefore, findings from this study suggest that topographic indices like TWI or topographic position index should be further explored as explanatory variables of within-field soil moisture and plant available water, especially if VRI is recommended.

-

Soil sensors have the potential to maintain the overall profitability of an irrigated field, while reducing water use, depending on several site-specific factors, such as the size of MZ, the number of sensors, and the variability within the field. To fully understand the benefit of soil sensors, farmers need to keep adequate irrigation records, such as timing, water use, and maintenance costs, to fully evaluate the profitability of their irrigated fields.

-

Future research and demonstration studies evaluating the profitability of irrigation, including VRI and soil sensors, should keep detailed records not only of irrigation amounts and dates but also the time the pivot takes to irrigate a specific zone, energy use per irrigation cycle, and cost of repairs and maintenance.

References

Alexandratos, N., & Bruinsma, J. (2012). World agriculture towards 2030/2050: the 2012 revision. ESA Working paper No. 12–03. Rome, FAO. Retrieved April 3, 2012 http://large.stanford.edu/courses/2014/ph240/yuan2/docs/ap106e.pdf.

Alves de Oliveira, R., Mota Ramos, M., & de Aquino, L. A. (2015). Irrigation water management. Sugarcane: Agricultural production, bioenergy, and ethanol (p. 170). Elsevier.

Andrade, M. A., O’Shaughnessy, S. A., & Evett, S. R. (2016). A GIS-based decision support tool for center pivot irrigation systems. In Proceedings of 2016 ASABE Annual International Meeting, Orlando, Florida, July 17–20, 2016. Paper Number: 162461449.

Bondesan, L., Ortiz, B. V., Morata, G. T., Damianidis, D., Jimenez, A-F., Vellidis, G., et. al. (2019). Evaluating and improving soil-sensor variable rate irrigation scheduling on farmers’ fields in Alabama. In: Proceedings of the 12th European Conference on Precision agriculture’19 (pp. 649–656). Montpellier, France: Wageningen Academic Publishers.

Boretti, A., & Rosa, L. (2019). Reassessing the projections of the world water development report. NPJ Clean Water, 2(15), 1–6. https://doi.org/10.1038/s41545-019-0039-9

Cartwright, E., Rabinowitz, A. N., Borron, A., Holt, J., & Smith, A. (2019). Factors motivating producer use of soil sensor technology. In: Proceedings of Southern Agricultural Economics Association (SAEA) Annual Meeting, Birmingham, Alabama, February 2–5, 2019.

Dahal, S., Phillipi, E., Longchamps, L., Khosla, R., & Andales, A. (2020). Variable rate nitrogen and water management for irrigated maize in the Western US. Agronomy, 10(10), 1533. https://doi.org/10.3390/agronomy10101533

Evans, R. G., & King, B. A. (2012). Site-specific sprinkler irrigation in a water-limited future. Transactions of ASABE, 55(2), 493–504.

Evett, S. R., Howell, T. A., Schneider, A. D., & Wanjura, D. F. (2002). Automatic drip irrigation control regulates water use efficiency. International Water and Irrigation, 22(2), 32–37.

Evett, S. R., O’Shaughnessy, S. A., Andrade, M. A., Kustas, W. P., Anderson, M. C., Schomberg, H. H., & Thompson, A. (2020). Precision agriculture and irrigation: Current U.S. perspectives. Transactions of the ASABE, 63(1), 57–67. https://doi.org/10.13031/trans.13355

Fridgen, J. J., Kitchen, N. R., Sudduth, K. A., Drummond, S. T., Wiebold, W. J., & Fraisse, C. W. (2004). Management Zone Analyst (MZA): Software for subfield management zone delineation. Agronomy Journal, 96(1), 100.

Gleeson, T., Wada, Y., Bierkens, M. F. P., & van Beek, L. P. H. (2012). Water balance of global aquifers revealed by groundwater footprint. Nature, 488, 197–200. https://doi.org/10.1038/nature11295

Hedley, B., & Yule, I. J. (2009). Soil water status mapping and two variable-rate irrigation scenarios. Precision Agriculture, 10, 342–355. https://doi.org/10.1007/s11119-009-9119-z

Howell, T., Yazar, A. A., Schneider, A. D., Dusek, D. A., & Copeland, K. S. (1995). Yield and water use efficiency of corn in response to LEPA irrigation. Transactions of the ASAE, 38(6), 1737–1747.

Irmak, S. (2015). Interannual variation in long-term center pivot–irrigated maize evapotranspiration and various water productivity response indices. II: Irrigation water use efficiency, crop wue, evapotranspiration wue, irrigation-evapotranspiration use efficiency, and precipitation use efficiency. Journal of Irrigation and Drainage Engineering, 141(5), 04014069.

Irmak, S., Burgert, M. J., Yang, H. S., Cassman, K. G., Walters, D. T., Rathje, W. R., Payero, J. O., Grassini, P., Kuzila, M. S., Brunkhorst, K. J., Eisenhauer, D. E., Kranz, W. L., VanDeWalle, B., Rees, J. M., Zoubek, G. L., Shapiro, C. A., & Teichmeier, G. J. (2012). Large-scale on-farm implementation of soil moisture-based irrigation management strategies for increasing maize water productivity. Transactions of the ASABE, 55(3), 881–894.

Irmak, S., Payero, J. O., Eisenhauer, D. E., Kranz, W. L., Martin, D. L., Zoubek, G. L., et al. (2006). Watermark granular matrix sensor to measure soil matric potential for irrigation management. Extension Circular, EC783. University of Nebraska. Retrieved April 5, 2021 from https://lancaster.unl.edu/ag/crops/watermark_sensor.pdf

Irmak, S., Rees, J. M., Zoubek, G. L., van DeWalle, B. S., Rathje, W. R., DeBuhr, R., et al. (2010). Nebraska agricultural water management demonstration network (NAWMDN): Integrating research and extension/outreach. Applied Engineering in Agriculture, 26(4), 599–613. https://doi.org/10.13031/2013.32066

Irmak, S., Sharma, V., Haghverdi, A., Jhala, A., Payero, J. O., & Drudik, M. (2021). Maize crop coefficients under variable and fixed (uniform) rate irrigation and conventional and variable rate fertilizer management in three soil types. Agricultural Water Management, 243, 106489. https://doi.org/10.1016/j.agwat.2020.106489

King, B., Wall, R., & Karsky, T. (2009). Center-pivot irrigation system for independent site-specific management of water and chemical application. Applied Engineering in Agriculture, 25(2), 187–198.

Kitchen, N. R., Drummond, S. T., Lund, E. D., Sudduth, K. A., & Buchleiter, G. W. (2003). Soil electrical conductivity and topography related to yield for three contrasting soil–crop systems. Agronomy Journal, 95, 483–495. https://doi.org/10.2134/agronj2003.4830

Kottek, M., Grieser, J., Beck, C., Rudolf, B., & Rubel, F. (2006). WorldMap of the Köppen-Geiger climate classification updated. Meteorologische Zeitschrift, 15, 259–263. https://doi.org/10.1127/0941-2948/2006/0130

Kramer, P. J. (1963). Water stress and plant growth. Agronomy Journal, 55(1), 31–35. https://doi.org/10.2134/agronj1963.00021962005500010013x

Kravchenko, A. N., & Bullock, D. G. (2000). Correlation of corn and soybean grain yield with topography and soil properties. Agronomy Journal, 92, 75–83. https://doi.org/10.2134/agronj2000.92175x

LaRue, J., & Evans, R. (2012). Considerations for variable rate irrigation. In: Proceedings of the 24th Annual Central Plains Irrigation Conference (pp. 111–116). Colby, Kansas.

Leininger, S. D., Krutz, L. J., Sarver, J. M., Gore, J., Henn, A., Bryant, C. J., et al. (2019). Establishing irrigation thresholds for furrow-irrigated peanuts. Crop Forage & Turfgrass Management, 5(1). https://doi.org/10.2134/cftm2018.08.0059

Lena, B., Ortiz, B. V., Jimenez, A.-F., Sanz-Saez, A., O’Shaughnessy, S., Durstock, M. K., et al. (2020). Evaluation of infrared canopy temperature data in relation to soil water-based irrigation scheduling in a humid subtropical climate. Transactions of the ASABE, 63(5), 1217–1231.

Liakos, V., Vellidis, G., Lacerda, L., Tucker, M., Porter, W., & Cox, C. (2018). Management zone delineation for irrigation based on Sentinel-2 Satellite images and field properties. In: Proceedings of the 14th International Conference on Precision Agriculture (unpaginated, online). Monticello, IL: International Society of Precision Agriculture.

Maestrini, B., & Basso, B. (2018). Drivers of within-field spatial and temporal variability of crop yield across the US Midwest. Scientific Reports, 8, 14833. https://doi.org/10.1038/s41598-018-32779-3

Mamedov, A. I., Levy, G. J., Shainberg, I., & Letey, J. (2001). Wetting rate, sodicity, and soil texture effects on infiltration rate and runoff. Soil Research, 39, 1293–1305. https://doi.org/10.1071/SR01029

Martini, E., Wollschläger, U., Musolff, A., Werban, U., & Zacharias, S. (2017). Principal component analysis of the spatiotemporal pattern of soil moisture and apparent electrical conductivity. Vadose Zone Journal. https://doi.org/10.2136/vzj2016.12.0129

Migliaccio, K. W., Morgan, K. T., Vellidis, G., Zotarelli, L., Fraisse, C., Zurweller, B. A., et al. (2016). Smartphone apps for irrigation scheduling. Transactions of ASABE, 59(1), 291–301.

Miller, K. A., Luck, J. D., Heeren, D. M., Lo, T., Martin, D. L., & Barker, J. B. (2018a). A geospatial variable rate irrigation control scenario evaluation methodology based on mining root zone available water capacity. Precision Agriculture, 19, 666–683. https://doi.org/10.1007/s11119-017-9548-z

Miller, L., Vellidis, G., Mohawesh, O., & Coolong, T. (2018b). Comparing a smartphone irrigation scheduling application with water balance and soil moisture-based irrigation methods: Part I—Plasticulture-grown Tomato. HortTechnolog, 28(3), 354–361. https://doi.org/10.21273/HORTTECH04010-18

Mondaca-Duarte, F. D., van Mourik, S., Balendonck, J., Voogt, W., Heinen, M., & van Henten, E. J. (2020). Irrigation, crop stress and drainage reduction under uncertainty: A scenario study. Agricultural Water Management, 230, 105990. https://doi.org/10.1016/j.agwat.2019.105990

NRCS. (2011). Soil Survey Staff. Natural Resources Conservation Service. United States Department of Agriculture. Web Soil Survey. Available http://websoilsurvey.sc.egov.usda.gov/. Accessed 06 June 2022.

O’Shaughnessy, S. A., & Evett, S. R. (2010). Canopy temperature based system effectively schedules and controls center pivot irrigation of cotton. Agricultural Water Management, 97(9), 1310–1316.

O’Shaughnessy, S. A., Evett, S. R., & Colaizzi, P. D. (2015). Dynamic prescription maps for site-specific variable rate irrigation of cotton. Agricultural Water Management, 159, 123–138. https://doi.org/10.1016/j.agwat.2015.06.001

O’Shaughnessy, S. A., Evett, S. R., Colaizzi, P. D., Andrade, M. A., Marek, T. H., Heeren, D. M., Lamm, F. R., & LaRue, J. L. (2019). Identifying advantages and disadvantages of variable rate irrigation—an updated review. Applied Engineering in Agriculture, 35(6), 837–852. https://doi.org/10.1331/aea.13128

O’Shaughnessy, S. A., Evett, S. R., Colaizzi, P. D., & Howell, T. A. (2012). Grain sorghum response to irrigation scheduling with the time-temperature threshold method and deficit irrigation levels. Transactions of ASABE, 55(2), 452–461.

Pan, L., Adamchuk, V. I., Martin, D. L., Schroeder, M. A., & Ferguson, R. B. (2013). Analysis of soil water availability by integrating spatial and temporal sensor-based data. Precision Agriculture, 14, 414–433. https://doi.org/10.1007/s11119-013-9305-x

Reyes, J., Wendroth, O., Matocha, C., & Zhu, J. (2019). Delineating site-specific management zones and evaluating soil water temporal dynamics in a farmer’s field in Kentucky. Vadose Zone Journal., 18, 180143. https://doi.org/10.2136/vzj2018.07.0143

Rinaldi, M., & He, Z. (2014). Chapter: Decision support systems to manage irrigation in agriculture. In Advances in agronomy (Vol. 123, pp. 229–279). Elsevier Inc. https://doi.org/10.1016/B978-0-12-420225-2.00006-6

Rogers, D. H. (2012). Introducing the Web-based version of KanSched: An ET-based Irrigation Scheduling Tool. In Proceedings of the 24th Annual Central Plains Irrigation Conference (pp. 203). Colby, Kansas.

Rudnick, D. R., Stockton, M., Taghvaeian, S., Warren, J., Dukes, M. D., Kremen, A., et al. (2020). Innovative Extension Methods in the U.S. to promote irrigation water management. Transactions of ASABE, 63(5), 1549–1558. https://doi.org/10.13031/trans.13929

Runge, M., Kelton, J., Birdsong, W., Dillard, B., & Balkcom, K. (2021). Enterprise budgets for row crops. Alabama Cooperative Extension Service. Reterived https://www.aces.edu/blog/topics/farm-management/enterprise-budgets-for-row-crops/. Accessed 20 June 2022.

Sadler, E. J., Evans, R. G., Stone, K. C., & Camp, C. R. (2005). Opportunities for conservation with precision irrigation. Journal of Soil and Water Conservation., 60(6), 371–379.

Sharma, V., & Irmak, S. (2020). Economic comparisons of variable rate irrigation and fertigation with fixed (uniform) rate irrigation and fertigation and pre-plant fertilizer management for maize in three soils. Agricultural Water Management, 240, 106307. https://doi.org/10.1016/j.agwat.2020.106307

Sharma, V., & Irmak, S. (2021). Comparative analyses of variable and fixed rate irrigation and nitrogen management for maize in different soil types: Part I. Impact on soil-water dynamics and crop evapotranspiration. Agricultural Water Management, 245, 106644.

Shi, X., Han, W., Zhao, T., & Tang, J. (2019). Decision support system for variable rate irrigation based on UAV multispectral remote sensing. Sensors, 19, 2880. https://doi.org/10.3390/s19132880

Sigua, G. C., Stone, K. C., Bauer, P. J., Szogi, A. A., & Shumaker, P. D. (2017). Impacts of irrigation scheduling on pore water nitrate and phosphate in coastal plain region of the United States. Agricultural Water Management, 186, 75–85.

Spencer, G. D., Krutz, L. J., Falconer, L. L., Henry, W. B., Henry, C. G., Larson E. J., et al. (2019). Irrigation water management technologies for furrow-irrigated corn that decrease water use and improve yield and on-farm profitability. Crop, Forage & Turfgrass Management, 5, 180100. https://doi.org/10.2134/cftm2018.12.0100

Stefanova, L., Misra, V., Chan, S., Griffin, M., O’Brien, J. J., & Smith, T. J., III. (2012). A proxy for high-resolution regional reanalysis for the Southeast United States: Assessment of precipitation variability in dynamically downscaled reanalyses. Climate Dynamics, 38, 2449–2466. https://doi.org/10.1007/s00382-011-1230-y

Stone, K. C., Bauer, P. J., O’Shaughnessy, S., Andrade-Rodriguez, A., & Evett, S. (2020). A variable-rate irrigation decision support system for corn in the U.S. u.s. eastern coastal plain. American Society of Agricultural and Biological Engineers, 63(5), 1295–1303. https://doi.org/10.1331/trans.13965

Sui, R., & Baggard, J. (2015). Wireless sensor network for monitoring soil moisture and weather conditions. Applied Engineering in Agriculture, 31(2), 193–200. https://doi.org/10.13031/aea.31.10694

Sui, R., & Voires, E. (2020). Comparison of Sensor-based and weather-based irrigation scheduling. Applied Engineering in Agriculture, 36(3), 375–386.

Sui, R., & Yan, H. (2017). Field study of variable rate irrigation management in humid climates. Irrigation and Drainage. https://doi.org/10.1002/ird.2111

Taghvaeian, S., Andales, A. A., Allen, L. N., Kisekka, I., O’Shaughnessy S. A., Porter D. O., et al. (2020). Irrigation scheduling for agriculture in the united states: The progress made and the path forward. Transactions of ASABE, 63(5), 1603–1618.

University of Georgia. (2021). Corn Production in Georgia. University of Georgia Extension. https://grains.caes.uga.edu/content/dam/caes-subsite/grains/docs/corn/2021-Corn-Production-Guide.pdf. Accessed 20 June 2022.

USDA-ERS. (2019). Irrigation and Water Use. https://www.ers.usda.gov/topics/farm-practices-management/irrigation-water-use/. Accessed 20 June 2022.

USDA-NASS. (2019). 2018 irrigation and water management survey. Series 2017 Census of Agriculture. Vol. 3, special studies, part 1. https://www.nass.usda.gov/Publications/AgCensus/2017/Online_Resources/Farm_and_Ranch_Irrigation_Survey/fris.pdf. Accessed 20 June 2022.

van Genuchten, M. T. (1980). A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Science Society of America Journal, 44(5), 892–898. https://doi.org/10.2136/sssaj1980.03615995004400050002x

Vellidis, G., Liakos, V., Perry, C., Porter, W., & Tucker, M. (2016a). Irrigation scheduling for cotton using soil moisture sensors, smartphone apps, and traditional methods. In Boyd, S., Huffman, M., & Robertson, B (Eds.), In: Proceedings of the 2016a Beltwide Cotton Conference (pp. 772–780). New Orleans: National Cotton Council, Memphis.

Vellidis, G., Liakos, V., Andreis, J. H., Perry, C. D., Porter, W. M., Barnes, E. M., Morgan, K. T., Fraisse, C., & Migliaccio, K. W. (2016b). Development and assessment of a smartphone application for irrigation scheduling in cotton. Computers and Electronics in Agriculture., 127, 249–259.

Vellidis, G., V. Liakos, W. Porter, M. Tucker, X. Liang. (2016c). A dynamic variable rate irrigation control system. In Proceedings of the 13th International Conference on Precision Agriculture. July 31—August 3, 2016c, St. Louis, Missouri, USA.

Vellidis, G., Tucker, M., Perry, C., Kvien, C., & Bednarz, C. (2008). A real-time wireless smart sensor array for scheduling irrigation. Computers and Electronics in Agriculture, 61(1), 44–50. https://doi.org/10.1016/j.compag.2007.05.009

Vellidis, G., Tucker, M., Perry, C., Reckford, D., Butts, C., Henry, H., et al. (2013). A soil moisture sensor-based variable rate irrigation scheduling system. In J. V. Stafford (Ed.), Precision agriculture ’13. Wageningen Academic Publishers. https://doi.org/10.3920/978-90-8686-778-3_88

Vories, E. D., & Evett, S. R. (2014). Irrigation challenges in the sub-humid U.S. Mid-South. International Journal of Water, 8(3), 259–274. https://doi.org/10.1504/IJW.2014.064220

Vories, E., O’Shaughnessy, S., Sudduth, K., Evett, S., Andrade, M., & Drummond, S. (2020). Comparison of precision and conventional irrigation management of cotton and impact of soil texture. Precision Agriculture. https://doi.org/10.1007/s11119-020-09741-3

Wakindiki, I. I. C., & Ben-Hur, M. (2002). Soil mineralogy and texture effects on crust micromorphology, infiltration, and erosion. Soil Science Society of America Journal, 66(3), 897–905. https://doi.org/10.2136/sssaj2002.8970